The two crescent inset panels serve as a direct replacement for compatible display equipment, allowing operations to maintain a consistent presentation and minimize downtime. Service teams can quickly install these replacements, reducing disruption to retail counters and display cases.

LongDescription#@#NA#@@#Cleaning Instructions#@#Wipe panels with a mild detergent and warm water using a soft cloth; rinse and dry immediately to prevent spotting. Sanitize high-touch zones like display edges and handles with an EPA-registered surface sanitizer per label dwell time. Inspect seals and fasteners weekly and tighten as needed. Clean spills promptly to deter pests and prevent material degradation. Regular cleaning maintains customer perception, reduces cross-contamination risk, and supports health code compliance.#@@#Additional Info#@#Hatco FSDT-INSET1 crescent inset panels replace worn parts on FSDT display cases, fit factory cutouts, weigh 1 pound, and ship as a matched pair; CSA-listed materials ensure durability for foodservice operations.#@@#General Info#@#Description #@#

The two crescent inset panels serve as a direct replacement for compatible display equipment, allowing operations to maintain a consistent presentation and minimize downtime. Service teams can quickly install these replacements, reducing disruption to retail counters and display cases.

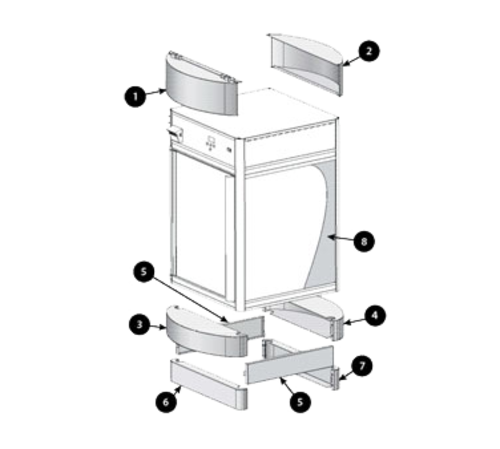

These panels fit FSDT models precisely, ensuring alignment with existing frame geometry and preserving seal integrity. Technicians will find that mounting points and contours match original specifications for reliable operation.

Manufactured to match the original material profile, the panels resist daily wear in front-of-house environments. Operators will maintain visual continuity while the components withstand routine cleaning and handling.

The crescent shape maintains the intended sight lines and product exposure within the display. Managers can uphold merchandising plans without needing to adjust shelving or lighting when the panels are back in service.

Supplying two panels in a single kit streamlines part ordering cycles and simplifies stock management for maintenance departments. Facilities staff can reduce lead time risk by keeping a compact spare on hand.

At approximately 1 pound per kit, the components allow for easy installation and safe manual handling. Maintenance crews can perform replacements without specialized lifting equipment.

Designed by the original manufacturer, the panels comply with the display case design parameters and part numbering system. Procurement teams will receive replacements that align with service records and warranty documentation.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Hatco FSDT-INSET1 panels monthly for mounting integrity and surface damage. It is crucial to remove any debris using a soft brush and to clean the surfaces with a neutral pH detergent diluted in water; after cleaning, rinse thoroughly and dry immediately to avoid moisture buildup. Additionally, tighten all fasteners to the manufacturer’s torque specifications and replace any worn gaskets to maintain optimal seal performance.