Stop sacrificing durability for fit. This curved hinged header adapts control-side installations on FSD and FSDT display cases, restoring alignment and sealing gaps that allow heat loss or moisture ingress. Food service technicians and facility managers can rely on engineered geometry and robust construction to maintain display case performance and appearance.

LongDescription#@#NA#@@#Cleaning Instructions#@#Clean high-touch areas like the curved hinged header, chair backs, menu covers, and door handles daily to prevent germ transfer and customer contamination. Mix mild detergent in warm water (use gallons or liters as needed) and wipe surfaces with a microfiber cloth, then apply an approved sanitizer per label contact time. Inspect for grime under shelves and seams; remove debris to deter pests. Document cleaning times and chemicals to support CSA and health inspections.#@@#Additional Info#@#Hatco FSD-CTLH curved hinged header fits FSD and FSDT bakery display cases for secure attachment and easy maintenance; it weighs 1 pound, mounts to factory points, and meets CSA electrical clearance guidelines.#@@#General Info#@#Description #@#

Stop sacrificing durability for fit. This curved hinged header adapts control-side installations on FSD and FSDT display cases, restoring alignment and sealing gaps that allow heat loss or moisture ingress. Food service technicians and facility managers can rely on engineered geometry and robust construction to maintain display case performance and appearance.

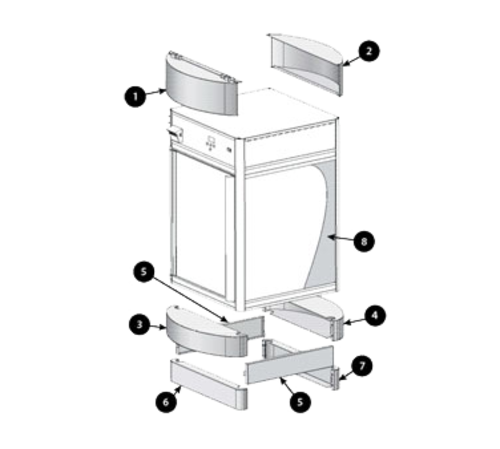

#@@# Curved Header#@#

Engineered curvature matches factory sealing profiles to reduce air infiltration along the control-side junction. Technicians achieve uniform contact across the header with minimal adjustment, preserving case thermal integrity and product hold times.

#@@# Hinged Design#@#

A full-length hinge permits rapid access for condenser, control, and electrical inspections without removing the assembly. Service staff complete routine maintenance faster, reducing downtime and labor hours during scheduled checks.

#@@# Control-Side Fit#@#

Machined mounting points align with original mounting holes on compatible FSD and FSDT frames to ensure repeatable installs. Installers eliminate trial-and-error fitting and maintain consistent spacing for control components and wiring routes.

#@@# Corrosion-Resistant Material#@#

Fabricated from a corrosion-resistant alloy and finished for commercial environments to withstand humidity and cleaning chemicals. Maintenance teams avoid premature replacement and preserve the aesthetic of front-of-house displays.

#@@# Lightweight Profile#@#

Weighing approximately 1 pound, the header provides a manageable balance of strength and handling for one-person installs. Field personnel transport and position the part safely, reducing the need for additional rigging or temporary supports.

#@@# Parts Compatibility#@#

Specifically designed for integration with FSD and FSDT series cases, the header interfaces with existing trim, gaskets, and control housings. Purchasing managers minimize parts mismatch risk and simplify spare-parts inventory by selecting a component matched to the platform.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Hatco FSD-CTLH curved hinged header weekly and tighten mounting hardware to prevent vibration. Clean surfaces with a soft cloth and mild detergent; avoid abrasive pads that scratch finishes. Lubricate hinge pivot points monthly with food-safe lubricant and cycle hinges to distribute lubricant. Verify alignment after reassembly and confirm CSA compliance labels remain visible. Document maintenance actions and replace worn parts promptly.