Stop trading countertop real estate for inconsistent cooling performance. This built-in flush top cold shelf delivers controlled cooling, high capacity, and a reliable duty cycle for food service operations that require steady chilled storage at the point of service. Designed for commercial kitchens, cafeterias, and hospital pantries, this unit balances energy usage and operational uptime with precise electronic temperature control.

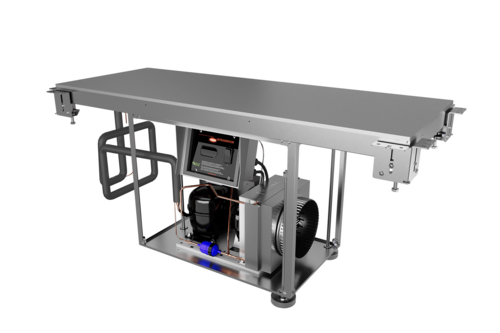

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the unit and remove contents. Wipe the aluminum top and interior with a mild soap solution and a soft cloth. Clean condenser coils and top-mount condensing unit monthly to maintain cooling efficiency and lower energy use. Degrease vents and oven adjacencies to reduce fire risk. Inspect door seals and controls; replace worn parts to avoid breakdowns. Dry all surfaces thoroughly before restoring power to prevent electrical hazards.#@@#Additional Info#@#Hatco’s CSBFP-36-S cold shelf measures 36" W x 36" D, uses 120v and 5.2 amps, with electronic controls and a top-mount condensing unit. It features aluminum construction, cULus certification, NEMA 5-15P plug, 440 watts, and weighs 151 pounds.#@@#General Info#@#Description #@#

Stop trading countertop real estate for inconsistent cooling performance. This built-in flush top cold shelf delivers controlled cooling, high capacity, and a reliable duty cycle for food service operations that require steady chilled storage at the point of service. Designed for commercial kitchens, cafeterias, and hospital pantries, this unit balances energy usage and operational uptime with precise electronic temperature control.

#@@# Top Mounted Condensing#@#

Electronic temperature control couples with a top-mounted condensing unit to maintain stable slab temperatures under heavy use. Operators can adjust settings quickly while the condensing assembly optimizes space below the counter for prep or storage.

#@@# Aluminum Hardcoat Construction#@#

Aluminum hardcoat construction provides a corrosion-resistant top that withstands daily service environments. Staff will find the surface durable for pans and containers, while maintenance routines remain straightforward.

#@@# R 290 Refrigerant#@#

The unit uses R 290 refrigerant to achieve efficient heat transfer with lower global warming potential than older refrigerants. Facilities that prioritize updated refrigerant profiles will reduce indirect environmental impact without sacrificing cooling capacity.

#@@# Compact Electrical Profile#@#

Rated for 120 volts at 5.2 amps and 60 hertz on a single-phase circuit, the shelf integrates into existing commercial electrical infrastructure with minimal upgrades. Technicians value clear electrical requirements for simplified installation and routine checks.

#@@# Performance Motor Output#@#

A 0.2 HP motor delivers consistent refrigeration performance while consuming 440 Watts, enabling continuous operation for high turnover service lines. Managers will note steady cooling rather than intermittent drops in temperature during peak periods.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect condenser fins weekly and remove debris with a soft brush to maintain heat exchange efficiency. Drain and sanitize drip pans monthly using a food-safe cleaner and hot water to prevent bacterial growth. Calibrate electronic temperature controls quarterly and verify operation at target setpoints with a certified thermometer. Replace door gaskets at first sign of cracking to preserve seal integrity. Flush refrigeration lines annually and confirm R-290 system pressure and leak-free joints.