Supplied with Manufacturer part number 2102681 for unambiguous identification, the strip supports accurate cross-referencing in parts catalogs and repair documentation. Facility engineers document installations using the part number to maintain traceable maintenance records.

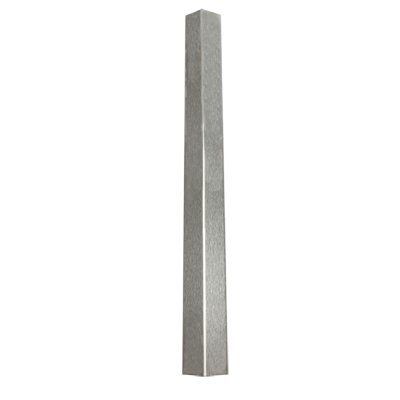

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the fryer and allow components to cool. Remove the Frymaster 2102681 top connecting strip and wipe with a mild detergent solution using a soft cloth. Rinse parts with clean water and dry completely before reinstalling. Clean surrounding surfaces to remove grease buildup and prevent fires. Inspect for wear and replace damaged parts to avoid breakdowns. Maintain coils and vents regularly to save energy and meet CSA and health inspection standards.#@@#Additional Info#@#Frymaster 2102681 top connecting strip measures 2" W x 21-3/8" D for commercial fryer assemblies. It ensures secure alignment, simplified installation, and is a durable, 1-pound unit meeting CSA guidelines.#@@#General Info#@#Description #@#

Supplied with Manufacturer part number 2102681 for unambiguous identification, the strip supports accurate cross-referencing in parts catalogs and repair documentation. Facility engineers document installations using the part number to maintain traceable maintenance records.#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Maintain the Frymaster 2102681 top connecting strip by inspecting fasteners and electrical contacts weekly to prevent looseness and intermittent connections. Use a nonabrasive cleaner and a lint-free cloth to remove grease; avoid solvents that degrade insulation. Verify alignment with adjacent units and tighten mounting screws to manufacturer torque values. Test continuity with a multimeter after cleaning. Document each service for CSA compliance and lifecycle planning.