Tackle high-volume washdown tasks with a heavy-duty utility spray valve that balances powerful rinse performance and operator comfort. This unit delivers a measured 2.15 GPM flow for efficient soil removal, while the extended squeeze lever minimizes operator fatigue during repetitive cycles. Food service managers and facility engineers will appreciate the valve's construction and serviceability, which support continuous operation in commercial kitchens and institutional settings.

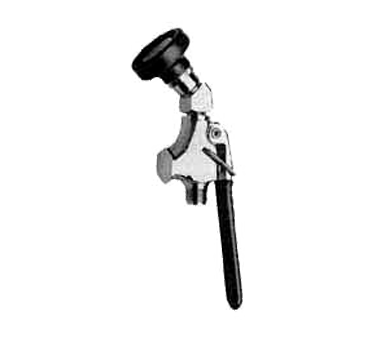

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug nearby equipment and shut water supply. Remove spray head and soak in warm, soapy water for 10 minutes. Scrub bronze surfaces with a soft brush and non-abrasive cleaner; rinse thoroughly. Inspect seals and replace worn parts per CSA guidelines. Flush supply lines before reassembly. Wipe exterior dry and test flow; verify 2.15 GPM performance. Clean weekly to reduce bacteria, prevent grease fires, lower energy use, and avoid costly breakdowns.#@@#Additional Info#@#Fisher 2920 utility spray valve delivers 2.15 GPM with a long lever and bronze construction for precise pre-rinse in high-volume kitchens; CSA-listed components and a 2-pound weight ensure robust daily use by foodservice professionals.#@@#General Info#@#Description #@#

Tackle high-volume washdown tasks with a heavy-duty utility spray valve that balances powerful rinse performance and operator comfort. This unit delivers a measured 2.15 GPM flow for efficient soil removal, while the extended squeeze lever minimizes operator fatigue during repetitive cycles. Food service managers and facility engineers will appreciate the valve's construction and serviceability, which support continuous operation in commercial kitchens and institutional settings.

#@@# Bronze Construction#@#

Bronze construction provides corrosion resistance suited to hard water and chlorinated environments common in commercial kitchens. Technicians will note that durable metal components reduce replacement frequency and maintain stable handling characteristics over time.

#@@# High Flow Output#@#

The spray valve produces 2.15 GPM at typical operating pressures, accelerating cleaning and shortening cycle times. Line planners can size plumbing runs and recovery systems with predictable water demand measured in gallons per minute.

#@@# Extended Squeeze Lever#@#

An extended squeeze lever reduces hand strain during long shifts and repetitive pre-rinse cycles. Maintenance staff will find that the ergonomic lever allows precise control of spray intensity, lowering the risk of operator fatigue.

#@@# Serviceable Design#@#

Technicians can quickly access internal components for routine maintenance or part replacement, minimizing downtime. Field service teams will complete repairs faster due to straightforward disassembly and standardized replacement parts.

#@@# Consistent Spray Pattern#@#

The valve delivers a consistent, concentrated spray that effectively removes soils from plates, pans, and equipment surfaces without excessive splashing. Supervisors can maintain kitchen throughput while controlling water usage, expressed in liters when converting specifications for regional reporting.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Fisher 2920 spray valve daily for spray pattern consistency and lever function. Flush supply lines monthly to remove sediment and verify flowrate at service connection. Lubricate the long squeeze lever pivot quarterly with food-grade lubricant to prevent wear. Replace worn seals and gaskets at first sign of leakage. Clean bronze surfaces with a nonabrasive cleaner and soft cloth. Maintain CSA-listed fittings and tighten loose connections to prevent water loss.