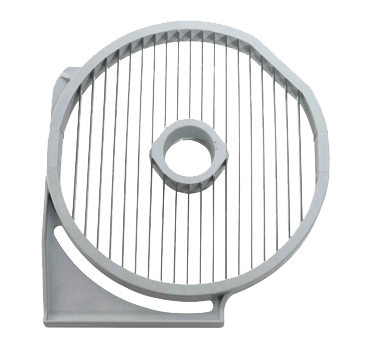

Stop settling for inconsistent cuts and slow throughput. This grid for chips transforms a food processor into a high-output dicing and slicing station that produces uniform 10mm cuts while preserving texture and yield. Operators gain consistent output and predictable portioning for high-volume fry lines, garnishes, and prep stations.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the food processor and remove the Electrolux 653573 grid. Rinse loose debris, then soak in a mild detergent solution for 5–10 minutes. Scrub with a soft brush along the 10mm openings to remove trapped starch and oil. Rinse with hot water and inspect for damage or warping. Sanitize per CSA or local regulations, air dry fully, and reassemble. Clean after each shift to prevent bacterial buildup, reduce fire risk from grease, and extend equipment life.#@@#Additional Info#@#Electrolux 653573 0.12 Grid for Chips fits commercial food processors, yielding 10mm slices for chips and fries. The stainless disc mounts quickly, reduces downtime, meets CSA compatibility, weighs 2 pounds, and supports high-volume operations.#@@#General Info#@#Description #@#

Stop settling for inconsistent cuts and slow throughput. This grid for chips transforms a food processor into a high-output dicing and slicing station that produces uniform 10mm cuts while preserving texture and yield. Operators gain consistent output and predictable portioning for high-volume fry lines, garnishes, and prep stations.

#@@# Grid Size#@#

The 10mm grid delivers consistent chip dimensions for predictable cooking times and uniform presentation. Chefs achieve repeatable results that simplify batch scheduling and reduce waste.

#@@# Durable Construction#@#

Stainless construction resists bending and withstands repeated installation and removal during shift changes. Maintenance teams can handle cleaning and inspection quickly, ensuring equipment remains in service.

#@@# Compatibility Range#@#

Designed to pair with compatible slicing discs and the wavy slicing disc, the grid integrates seamlessly into existing processor setups without requiring new drives or adaptors. Kitchens can expand functionality using parts already available.

#@@# Throughput Efficiency#@#

Operators experience faster prep times because the grid processes whole product volumes in a single pass, minimizing manual knife work and labor hours. Line managers can schedule production more tightly with reliable cycle times.

#@@# Compact Profile#@#

Slim dimensions and low height allow for storage in tight tool cabinets and prompt access during service peaks. Staff can place it on prep counters without sacrificing workspace ergonomics.

#@@# Compliance Marking#@#

Manufactured to recognized commercial standards and supplied by an established equipment maker founded in 1998, the grid aligns with professional kitchen expectations for replacement parts. Purchasing teams can document traceability and service histories with the supplied part number.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Handle the Electrolux 653573 grid with routine care to maintain cutting precision and reduce downtime. Inspect the 10mm grid visually before each shift and remove trapped debris with a soft brush. Rinse under warm water and apply a mild, food-safe detergent; scrub gently to avoid damage. Sanitize per facility protocol, then air-dry fully before reassembly. Lubricate mounting points lightly and confirm CSA-compliant connectors remain tight and corrosion-free.