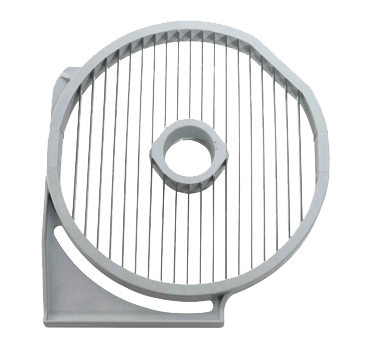

Optimize chip production with a precision grid that balances throughput and uniform cut quality for high-volume kitchens. Designed for integration with industrial food processors, this 8mm grid delivers consistent 5/16 inch slices and enables rapid processing of large potato batches without sacrificing dimensional accuracy. Operators gain predictable output rates while maintenance teams benefit from simple mounting and limited service requirements.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug and remove the grid. Rinse debris under warm water, then scrub with a soft brush and mild detergent to remove oil and starch. Inspect holes for clogs; clear with a toothpick if needed. Sanitize with a CSA-approved solution, rinse, and air dry completely before reinstalling. Clean vents and adjoining parts weekly to prevent grease buildup, reduce fire risk, lower energy use, and extend equipment life.#@@#Additional Info#@#Electrolux 653572 8mm chip grid fits food processors, delivering 5/16" cuts for fries and chips. Stainless mounting, 0.88" height, 8.25" width, CSA-rated, 2-pound weight, designed for professional foodservice.#@@#General Info#@#Description #@#

Optimize chip production with a precision grid that balances throughput and uniform cut quality for high-volume kitchens. Designed for integration with industrial food processors, this 8mm grid delivers consistent 5/16 inch slices and enables rapid processing of large potato batches without sacrificing dimensional accuracy. Operators gain predictable output rates while maintenance teams benefit from simple mounting and limited service requirements.

#@@# Grid Compatibility#@#

This grid mates directly with standard slicing disc towers used in commercial food processors, ensuring secure engagement and stable rotation during high-speed operation. Technicians can install the unit quickly and maintain alignment without specialized tooling, which reduces downtime between shifts.

#@@# Cut Specification#@#

The grid yields 8mm, 5/16 inch cuts that maintain uniform thickness across varied potato sizes, improving frying consistency and oil absorption rates. Chefs achieve repeatable texture and cooking time, enabling menu items to meet target specifications batch after batch.

#@@# Construction Durability#@#

Manufacturers build the grid from corrosion-resistant metal to withstand repeated exposure to wash cycles and food acids in high-use environments. Supervisors observe a prolonged service life compared with consumer-grade alternatives, lowering part replacement frequency and spare part spending.

#@@# Throughput Performance#@#

Operators process large volumes through the grid without bottlenecking the food preparation line, thanks to an open pattern that minimizes clogging during continuous slicing. Shift leads maintain steady production output and reduce queuing at staging stations.

#@@# Maintenance Simplicity#@#

Staff perform cleaning and inspection using standard sanitizing procedures; the grid design allows thorough debris removal from the slicing openings and attachment points. Safety teams appreciate that routine checks expose wear indicators before performance degrades.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Electrolux 653572 grid before each shift for bent wires, cracks, or residue that can impair slicing accuracy. Remove debris with a soft brush and warm, soapy water; rinse and air dry to prevent corrosion. Sanitize using an approved food-safe solution following manufacturer dwell times. Store the grid in a dry, ventilated area to avoid moisture buildup. Replace the grid if holes enlarge or alignment deforms to maintain consistent chip dimensions.