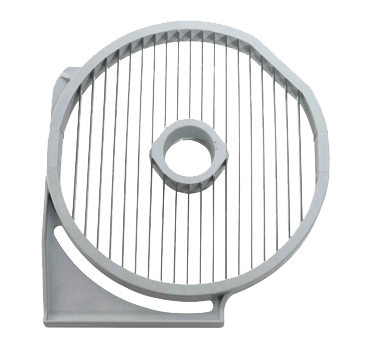

Stop compromising cut quality for output. This grid transforms a commercial food processor into a high-capacity chip production tool that yields uniform cuts while maintaining throughput. Designed for continuous use in professional kitchens, the component installs quickly and sustains consistent slice dimensions across large batches.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the food processor and remove blades. Fit the Electrolux 653571 6mm grid as instructed. Wash grid in warm, soapy water or run through a high-temperature dishwasher. Rinse thoroughly to remove debris. Inspect for damage and replace if bent. Dry completely before reinstalling to prevent corrosion and bacteria. Clean the feed chute and slicing discs after each use to prevent grease buildup and ensure equipment efficiency and CSA compliance.#@@#Additional Info#@#Electrolux 653571 6mm grid for chips fits compatible food processors, sections products into uniform 6mm cuts. Stainless steel resists corrosion, allows quick install, and meets CSA specs for commercial kitchens.#@@#General Info#@#Description #@#

Stop compromising cut quality for output. This grid transforms a commercial food processor into a high-capacity chip production tool that yields uniform cuts while maintaining throughput. Designed for continuous use in professional kitchens, the component installs quickly and sustains consistent slice dimensions across large batches.

#@@# Grid Size#@#

The 6mm grid produces consistent 1/4 inch cuts suited for fries and uniform root vegetable chips. Operators achieve predictable cook times and portion control because each piece measures within narrow tolerances, ensuring a high standard of quality.

#@@# Durable Construction#@#

Stainless components resist deformation under repetitive loading and preserve cutting geometry over thousands of cycles. Technicians reduce replacement frequency and maintain production quality with less downtime, enhancing overall efficiency.

#@@# Compatibility Fit#@#

The grid pairs with standard slicing discs and the wavy slicing disc configuration to expand product output options. Service teams can install the plate without tools in most Electrolux processor housings, significantly shortening changeover time and improving workflow.

#@@# Throughput Efficiency#@#

Sharp, closely spaced teeth channel product through the grid rapidly, enabling high-volume processing without manual rework. Kitchen staff can increase hourly yields while maintaining consistent portion weights, contributing to better operational performance.

#@@# Sanitation Access#@#

Smooth surfaces and an open grid design permit thorough cleaning and allow inspectors to verify residue removal visually. Maintenance crews can complete wash cycles faster, meeting sanitation protocols and reducing labor minutes, which is crucial in busy kitchen environments.

#@@# Replacement Reliability#@#

OEM-quality manufacture aligns tolerances with original equipment, ensuring secure seating and minimal vibration during operation.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Electrolux 653571 0.12 Grid for chips before each shift to ensure secure mounting and no burrs or deformation. Remove food debris with warm water and a non-abrasive brush; use mild detergent for oil and rinse thoroughly. Sanitize with a food-safe solution as per dilution instructions, then air-dry on a clean rack to avoid corrosion. Lubricate moving mounts per manufacturer guidance and torque fasteners to specified values.