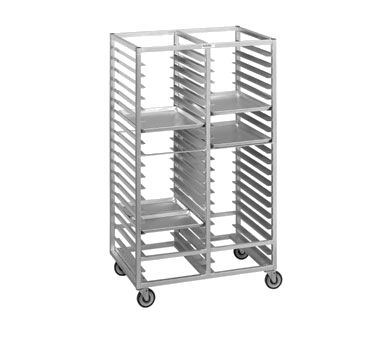

Handle high tray volumes with engineered efficiency and durable construction. This cafeteria tray rack supports continuous meal service in schools, hospitals, and large foodservice operations while minimizing handling time and floor congestion. Designed for professionals who demand predictable performance, the unit balances capacity and mobility without compromising corrosion resistance.

LongDescription#@#NA#@@#Cleaning Instructions#@#Wipe aluminum frame and tray guides with a mild detergent solution and soft cloth; rinse and dry immediately to prevent corrosion. Disinfect high-touch zones like handles and caster stems using an EPA-registered sanitizer per label contact time. Inspect casters weekly and tighten hardware. Remove crumbs from rack crevices to deter pests. Regular cleaning prevents cross-contamination, supports health-code compliance, and preserves finish and service life.#@@#Additional Info#@#Channel 467A3 Cafeteria Tray Rack holds 20 trays in a 45" W x 30" D x 36" H aluminum frame. It features 5" angle spacing, two trays per level, and rolls on 5" swivel casters. NSF and CSA certified, it weighs 28 pounds.#@@#General Info#@#Description #@#

Handle high tray volumes with engineered efficiency and durable construction. This cafeteria tray rack supports continuous meal service in schools, hospitals, and large foodservice operations while minimizing handling time and floor congestion. Designed for professionals who demand predictable performance, the unit balances capacity and mobility without compromising corrosion resistance.

#@@# Capacity Optimization#@#

Configure storage for twenty standard 15 x 20 trays using a double-section layout that stores two trays per level and maintains 5-inch angle spacing for secure separation. This arrangement reduces tray jams and simplifies loading during peak service by keeping trays organized and accessible.

#@@# Lightweight Aluminum Frame#@#

Specify an aluminum construction that resists rust and reduces overall weight to twenty-eight pounds, enabling staff to move the rack with less exertion while preserving structural integrity. This material choice lowers long-term maintenance compared with painted steel and suits wet cleaning protocols.

#@@# End Loading Access#@#

Place trays from the end with a side-load orientation that accelerates placement and retrieval in tight lines, improving throughput in crowded serving lines. This loading style supports linear workflows and reduces the need for staff to reach across the unit.

#@@# Smooth Mobility System#@#

Depend on four 5-inch swivel stem casters model CSS45O to provide responsive steering and stable travel across kitchen and cafeteria floors. This caster configuration delivers maneuverability during transfers between the dish room and service line while supporting the rack height and loaded trays.

#@@# Compact Footprint#@#

Position a 45-inch wide by 30-inch deep footprint with a 36-inch height to fit standard service corridors and tray stations without excessive floor space usage. This compact geometry allows placement near service counters and trolleys while preserving aisle clearance for staff carts.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Maintain the Channel 467A3 tray rack by inspecting casters weekly and tightening mounting hardware to prevent wobble and ensure stability during use. Clean aluminum surfaces with a neutral pH detergent and a soft cloth; rinse thoroughly to avoid any residue that could affect performance. Lubricate swivel stems lightly with food-grade lubricant every three months to ensure smooth operation. Verify that NSF compliance labels remain legible and intact.