Serve high volumes without sacrificing holding consistency with a heavy-duty stainless steel countertop sandwich warmer designed for food service environments that require precise temperature control and reliable uptime. This unit supports extended display runs and reduces product waste by maintaining stable heat across a single slanted shelf, while the 120/208v electrical configuration and 1.23kW power draw match common commercial power systems for predictable operation.

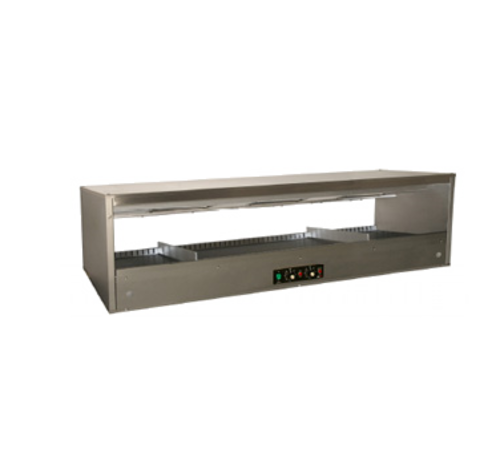

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the unit and remove food. Wipe interior and slanted wire shelf with mild soap and warm water; rinse and dry. Clean ceramic infrared top and stainless exterior with non-abrasive cloth. Remove grease from vents and bottom areas to lower fire risk. Vacuum condenser coils and check seals to improve efficiency and prevent breakdowns. Sanitize food-contact surfaces to stop bacterial spread and meet CSA inspection standards. Restore power only when fully dry.#@@#Additional Info#@#The BKI SM-6224L stainless steel sandwich warmer has a 62" x 24" footprint, one slanted wire shelf, and ceramic infrared top heat.#@@#General Info#@#Description #@#

Serve high volumes without sacrificing holding consistency with a heavy-duty stainless steel countertop sandwich warmer designed for food service environments that require precise temperature control and reliable uptime. This unit supports extended display runs and reduces product waste by maintaining stable heat across a single slanted shelf, while the 120/208v electrical configuration and 1.23kW power draw match common commercial power systems for predictable operation.

#@@# Thermostatic Controls#@#

Individual thermostatic controls provide targeted temperature regulation so staff can set holding conditions to match product needs. Operators achieve repeatable results and minimize overcooking during long service periods.

#@@# Ceramic Infrared Heat#@#

Ceramic infrared top heat delivers direct radiant warmth that preserves texture while keeping items visibly appealing. Infrared transfer heats surfaces efficiently, reducing heat loss compared with convective methods.

#@@# Slanted Wire Shelf#@#

A slanted wire shelf promotes product visibility and passive drainage of excess grease or oils while supporting uniform airflow. Staff gain easier access for restocking and presentation without compromising heat distribution.

#@@# Stainless Steel Construction#@#

Durable stainless steel construction resists corrosion and facilitates daily cleaning to meet sanitation protocols and operational uptime goals. Maintenance teams find smooth surfaces and welded seams simplify sanitation checks.

#@@# Electrical Compatibility#@#

The 120/208v, 60 Hz, single-phase electrical design with NEMA L14-20P plug and 6.51 amp draw fits commercial power infrastructures and reduces the need for custom wiring. Facilities planners can integrate the unit with existing circuits and track load requirements precisely.

#@@# Countertop Configuration#@#

Countertop footprint with 62 by 24 inches overall footprint and 4 inch legs allows placement on service counters without built-in modifications.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect electrical connections weekly and tighten the NEMA L14-20P plug and cord strain relief to prevent arcing. Clean ceramic infrared elements and reflectors with a soft brush when the unit is off and cool. Remove crumbs and debris from the slanted wire shelf daily; soak it in warm, soapy water and air dry before reinstalling. Verify thermostatic controls calibrate within 5°F by comparing the display to a certified probe thermometer.