Stop compromising speed for consistent heat retention. This stainless steel countertop sandwich warmer delivers controlled, visible warming while fitting compact footprints for high-traffic service lines. Designed for continuous use in institutional and commercial settings, this unit combines ceramic infrared top heat with a bottom wire shelf to maintain product texture and temperature during peak periods.

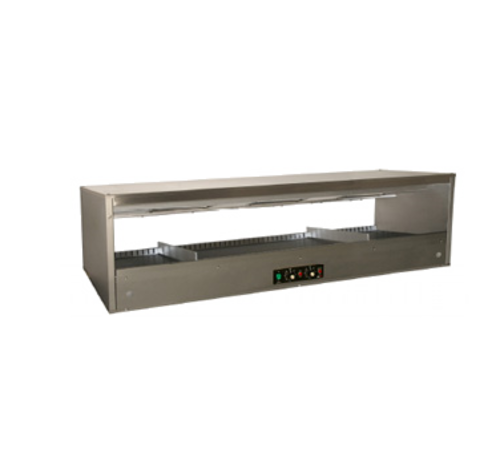

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the unit before cleaning. Remove pans and wipe surfaces with a mild soap solution and soft cloth. Gently scrub the ceramic top and wire shelf; avoid abrasive pads. Clean stainless steel exterior with a non-abrasive cleaner, following the grain. Vacuum condenser and vents to remove grease and dust. Dry all parts completely. Check door seals and leg fasteners; tighten or replace as needed. Clean weekly to reduce bacteria, cut fire risk, lower energy use, and prevent equipment failure.#@@#Additional Info#@#BKI’s SM-51 countertop sandwich warmer features 51" of stainless steel display, one wire shelf, ceramic infrared top heat, individual thermostatic controls, and 4" legs. It operates at 120 volts, 1800 watts, and supports pass-thru merchandising.#@@#General Info#@#Description #@#

Stop compromising speed for consistent heat retention. This stainless steel countertop sandwich warmer delivers controlled, visible warming while fitting compact footprints for high-traffic service lines. Designed for continuous use in institutional and commercial settings, this unit combines ceramic infrared top heat with a bottom wire shelf to maintain product texture and temperature during peak periods.

#@@# Thermostatic Controls#@#

Operators gain precise temperature regulation through individual thermostatic controls that respond quickly to setpoint changes. Technicians can adjust heat without interrupting service, ensuring consistent holding conditions across varied product loads.

#@@# Infrared Top Heat#@#

Ceramic infrared elements provide directed, radiant warming that preserves crust and surface quality while reducing moisture loss. Managers will observe reduced product sag and improved appearance for sandwiches and prepared items.

#@@# Stainless Steel Build#@#

Fabrication in stainless steel resists corrosion and stands up to daily cleaning protocols common in kitchens and cafeterias. Supervisors receive a durable unit that minimizes downtime and lowers lifecycle maintenance demands.

#@@# Countertop Configuration#@#

Compact design allows placement on counters for pass-thru workflow, saving floor space and keeping staff within efficient reach of service lines. Kitchen teams can integrate the unit into existing stations without major layout changes.

#@@# Adjustable Shelfing#@#

A single flat wire shelf supports standard pans and accommodates height variation through slot dividers, enabling operators to organize multiple product types. Food service staff obtain quick access and clear product separation during service.

#@@# Safety And Compliance#@#

ETL and cETL sanitation listings validate electrical safety and hygiene standards for institutional use, supporting purchasing requirements for schools, hospitals, and hospitality providers.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect heating elements weekly and tighten electrical connections to maintain the BKI SM-51 performance. Clean interior surfaces with a mild detergent and rinse; avoid abrasive pads that scratch stainless steel. Remove crumb and grease buildup from ceramic infrared top heat and from the wire shelf to prevent hotspots. Verify thermostatic controls calibrate to setpoints and replace worn gaskets. Level unit on 4" legs and test safety listings such as ETL and cETL regularly.