Stop compromising heat retention for display capacity. This stainless steel countertop sandwich warmer combines robust construction with precise temperature control to keep filled sandwiches, wraps, and prepared entrees at consistent holding temperatures while maintaining an attractive presentation for high-traffic service lines. Designed for continuous use in institutional and commercial settings, the unit delivers reliable performance on standard 120 volts electrical service.

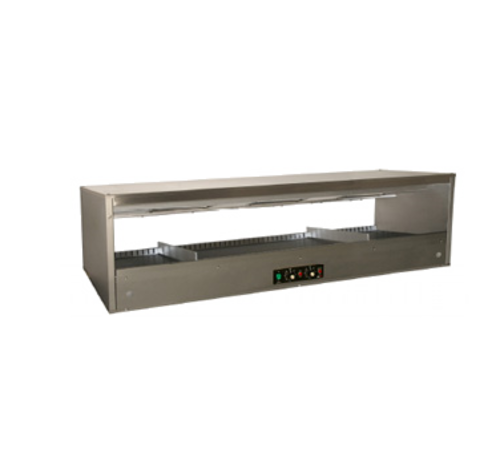

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the unit and remove food. Wipe interior with mild soap and warm water, scrub wire shelf, dry completely. Clean ceramic infrared top and stainless exterior with non-abrasive cleaner. Vacuum condenser area and check vents to remove grease and dust. Inspect door seals and legs; tighten hardware. Sanitize food-contact surfaces per CSA or local codes. Regular cleaning prevents contamination, reduces fire risk, lowers energy use, and extends equipment life.#@@#Additional Info#@#BKI’s SM-3824R stainless steel sandwich warmer measures 38" x 24" with a slanted wire shelf and ceramic infrared heat.#@@#General Info#@#Description #@#

Stop compromising heat retention for display capacity. This stainless steel countertop sandwich warmer combines robust construction with precise temperature control to keep filled sandwiches, wraps, and prepared entrees at consistent holding temperatures while maintaining an attractive presentation for high-traffic service lines. Designed for continuous use in institutional and commercial settings, the unit delivers reliable performance on standard 120 volts electrical service.

#@@# Construction Integrity#@#

Built with stainless steel panels and a wire bottom shelf, the unit resists corrosion and holds structural alignment under daily use. Designers specified a slanted shelf and slot divider to maintain organized product staging while minimizing contact points that accelerate wear.

#@@# Precise Temperature Control#@#

Individual thermostatic controls allow operators to set and maintain target holding temperatures for product safety and quality. Frequent adjustments remain simple because the controls respond quickly and deliver repeatable results across shifts.

#@@# Infrared Ceramic Top Heat#@#

A ceramic infrared top heat element supplies direct radiant energy that preserves crust texture and reduces moisture loss in held items. Kitchen staff achieve consistent surface finish without overcooking internal fillings.

#@@# Countertop Presentation Design#@#

The slanted shelf and slotted divider improve product visibility and promote first-in, first-out handling for high throughput environments. Display staff reduce retrieval time while customers see food clearly, increasing perceived freshness.

#@@# Electrical Compatibility#@#

The unit operates on 120v/60/1-ph power drawing 7.13 amps and 0.86 kW, and ships with a 6-foot cord terminated by a NEMA 5-15P for plug-in installation. Technicians encounter straightforward integration into existing circuits without special wiring.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect seals and hinges weekly; replace damaged gaskets to maintain heat retention and reduce energy draw. Clean stainless steel surfaces with a soft cloth and neutral detergent; avoid chlorine and abrasive pads. Remove crumb and grease buildup from the wire shelf and ceramic infrared elements after each service day; allow components to cool before cleaning. Test thermostatic controls at setpoints and record readings monthly.