Built to handle continuous service, this commercial countertop sandwich warmer balances capacity with precise temperature control to keep hot menu items ready and consistent. Operators will appreciate two thermostatic zones and ceramic infrared top heat that maintain even warming across slanted shelves, reducing downtime and food waste. Designed for heavy use with stainless steel construction and a right-side cord, this unit supports fast-paced lines without sacrificing reliability.

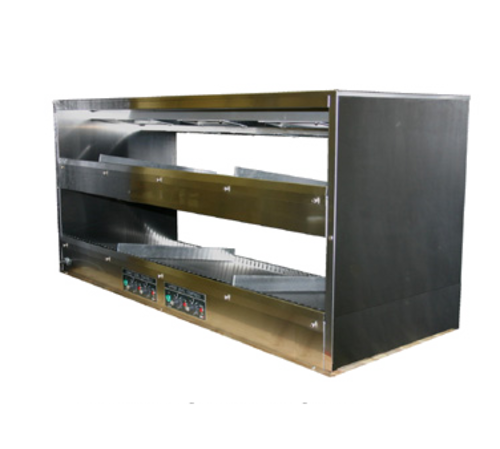

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug unit and allow cooling before cleaning. Remove shelves and dividers; wash with mild detergent and warm water, rinse, and dry. Clean stainless exterior with non-abrasive cleaner and soft cloth. Vacuum condenser coils monthly to improve efficiency and reduce energy use. Inspect door seals and power cord; replace damaged parts. Regular cleaning removes bacteria, cuts fire risk from grease, lowers utility costs, and helps pass CSA inspections.#@@#Additional Info#@#BKI’s 2TSM-6224R sandwich warmer measures 62" W x 24" D, has two slanted stainless steel shelves, ceramic infrared heat, and individual thermostatic controls.#@@#General Info#@#Description #@#

Built to handle continuous service, this commercial countertop sandwich warmer balances capacity with precise temperature control to keep hot menu items ready and consistent. Operators will appreciate two thermostatic zones and ceramic infrared top heat that maintain even warming across slanted shelves, reducing downtime and food waste. Designed for heavy use with stainless steel construction and a right-side cord, this unit supports fast-paced lines without sacrificing reliability.

#@@# Countertop Design#@#

Engineers optimized the footprint at 62 inches wide by 24 inches deep to fit behind service counters while maximizing display area. Customers will see products clearly on the slanted shelves, and staff will access trays quickly during peak periods.

#@@# Dual Zone Controls#@#

Technicians equipped the unit with individual thermostatic controls for each shelf, enabling separate temperature settings for different items. Kitchens can hold fried sandwiches on one shelf and grilled wraps on the other while preserving product integrity.

#@@# Infrared Top Heat#@#

Manufacturers specified ceramic infrared elements for top heating to deliver direct, consistent heat that reduces hot spots. Chefs will retain crisp textures and even internal temperatures across product loads.

#@@# Stainless Construction#@#

Fabricators built exterior, interior, and shelf components from stainless steel to resist corrosion and simplify sanitation. Cleaning crews will spend less time on maintenance and more time on core operations.

#@@# Electrical Configuration#@#

Designers supplied a 120/208v, single phase electrical system drawing 13.02 amps and 2.46kW with a NEMA L14-20P cord on the right for secure connection. Facilities teams can plan supply and breakers accordingly to avoid service interruptions.

#@@# Capacity And Support#@#

Engineers included two slanted stainless shelves plus a bottom wire shelf and 4-inch legs to support heavy product weights and promote airflow.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Clean condenser and infrared emitters weekly to maintain efficiency and reduce energy draw. Inspect and tighten electrical connections monthly; verify cord orientation and NEMA L14-20P plug integrity. Calibrate thermostatic controls quarterly with a traced thermometer and adjust setpoints to match target temperatures. Degrease stainless steel surfaces with a neutral pH cleaner and soft cloth; avoid chlorides and steel wool.