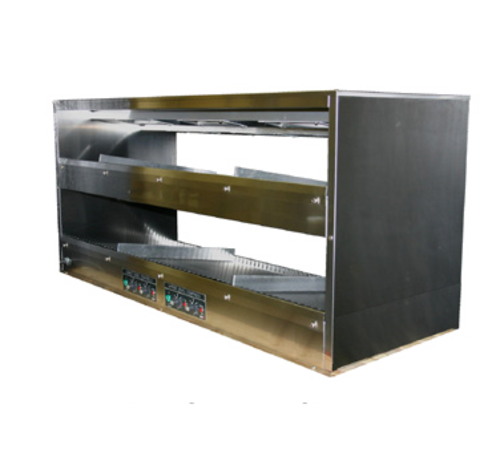

Built for continuous service, this stainless steel countertop sandwich warmer delivers consistent heat control and an organized display for high-traffic foodservice lines. Designed with two slanted shelves and ceramic infrared top heat, it maintains product temperature while preserving appearance and portioning. Engineers specified a 120/208 volts electrical system with a NEMA L14-20P cord on the left to match commercial power layouts and reduce installation time.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug unit before cleaning. Remove shelves; wash with warm, soapy water, rinse, and dry. Wipe interior and slanted back with mild detergent and a non-abrasive cloth. Clean exterior stainless steel with a soft cloth and approved cleaner following the grain. Vacuum condenser and vents to remove grease; inspect and clean coils quarterly. Verify door seals and thermostatic controls before reconnecting power.#@@#Additional Info#@#BKI’s 2TSM-3824L sandwich warmer is 38" W x 24" D, made of stainless steel, with two slanted shelves, ceramic infrared heat, individual thermostats, a bottom shelf, 4" legs, and operates at 120/208v 1-Ph, 9.18 amps with a NEMA L14-20P cord.#@@#General Info#@#Description #@#

Built for continuous service, this stainless steel countertop sandwich warmer delivers consistent heat control and an organized display for high-traffic foodservice lines. Designed with two slanted shelves and ceramic infrared top heat, it maintains product temperature while preserving appearance and portioning. Engineers specified a 120/208 volts electrical system with a NEMA L14-20P cord on the left to match commercial power layouts and reduce installation time.

#@@# Thermostatic Controls#@#

Operators can adjust independent thermostats for each shelf to match holding temperatures for distinct menu items. These controls provide reliable setpoint stability and reduce product loss from temperature fluctuations.

#@@# Ceramic Infrared Heat#@#

Ceramic infrared elements supply direct radiant warmth that preserves crust and texture without overcooking. These elements accelerate recovery after door openings, supporting rapid service cycles.

#@@# Slanted Shelf Design#@#

Slanted shelves present items at a clear angle for merchandising and allow gravity-assisted drainage of condensation. The shelf geometry works with slot dividers to keep portions separated and visually consistent.

#@@# Stainless Steel Construction#@#

The stainless steel exterior and shelf construction withstand daily sanitation protocols and resist corrosion in demanding kitchens. Smooth surfaces simplify cleaning and support HACCP practices.

#@@# Compact Countertop Footprint#@#

Countertop installation saves floor space while offering a 38-inch width and 24-inch depth to fit typical pass-through counters. Four-inch legs provide clearance for routine cleaning and connection to floor drains.

#@@# Electrical Specification#@#

The unit operates at 120/208v, 60 Hz, single phase, drawing 9.18 amps and consuming 1.73 kW for predictable energy planning. ETL and cETL listings confirm compliance with recognized safety and sanitation standards.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Service teams must inspect condenser areas weekly and remove debris to maintain airflow. Rotate thermostatic controls monthly and verify temperature response with a calibrated probe. Lubricate hinge points quarterly and tighten electrical connections to prevent heating. Clean stainless steel surfaces after each shift with a neutral detergent; avoid chlorides. Verify NEMA L14-20P cord integrity and leg mounting torque during safety audits.