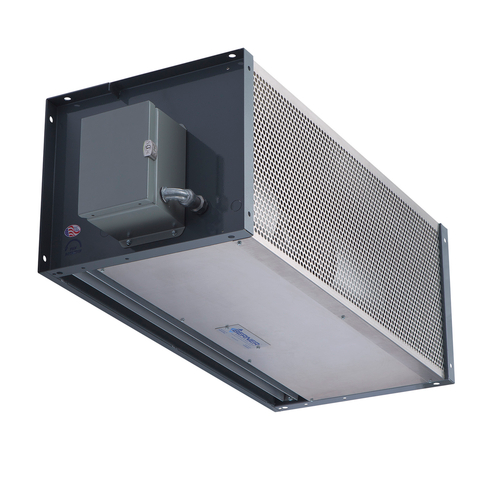

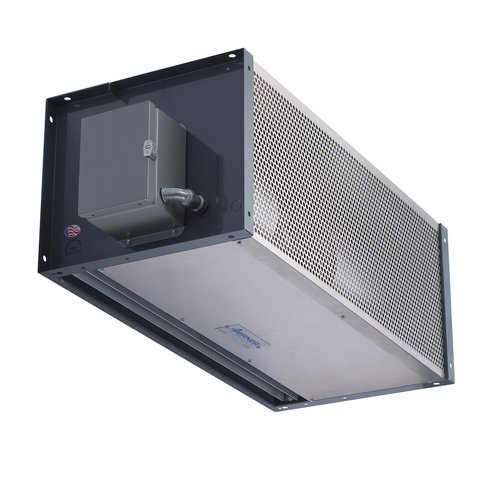

Stop compromising climate control for throughput. This industrial air curtain delivers controlled airflow and proven separation performance while supporting high door traffic in commercial kitchens, hospitals, and hospitality properties. Installed for interior mounting, this unit fits wide openings and supplies targeted air management for environmental separation and insect control.

LongDescription#@#NA#@@#Cleaning Instructions#@#Wipe exterior housing and inlet screen daily with a mild detergent and soft cloth; scrub crevices around mounting brackets to remove grease and crumbs. Rinse with clean water and dry immediately. Sanitize high-touch surfaces like control switches and access panels using an EPA-registered disinfectant per label dwell time. Inspect and remove debris from motor intakes monthly to prevent pest attraction and contamination of food-prep areas.#@@#Additional Info#@#Berner’s IDC14-2096A-1 air curtain, 85" wide, runs at 120 volts with two 1 HP motors, protecting openings up to 14 feet for separation and 12 feet for insects; interior mount, cULus certified, 267 pounds, for continuous commercial use.#@@#General Info#@#Description #@#

Stop compromising climate control for throughput. This industrial air curtain delivers controlled airflow and proven separation performance while supporting high door traffic in commercial kitchens, hospitals, and hospitality properties. Installed for interior mounting, this unit fits wide openings and supplies targeted air management for environmental separation and insect control.

#@@# Motor Redundancy#@#

Two independent 1 HP motors provide redundant power and maintain continuous airflow during heavy use. Maintenance staff benefit from reduced single point failures, and operators notice consistent performance across long service periods.

#@@# Coverage For Tall Openings#@#

Designed to serve openings up to 14 feet high for environmental separation and 12 feet high for insect protection, this unit handles large pass-throughs in food service and institutional facilities. Engineers can size the system confidently for tall doors without overspecifying equipment.

#@@# Direct Drive Efficiency#@#

Direct drive configuration eliminates belts and pulleys, improving mechanical efficiency and reducing routine adjustments. Technicians complete service faster, and facilities reduce downtime related to belt replacement.

#@@# Interior Mounting Design#@#

Configured for interior mounting, the assembly integrates with existing soffits or mounting frames to preserve exterior facades. Facility teams gain easier access for service while avoiding exterior exposure during adverse weather.

#@@# Durable Construction#@#

Manufactured in the USA with a robust housing and inlet screen, the air curtain resists corrosion and debris ingestion in commercial environments. Operations staff appreciate the lower lifecycle costs from fewer component replacements.

#@@# Electrical Compatibility#@#

Rated for 120 volts, single phase, 60 hertz operation, the unit installs on standard commercial circuits without special power infrastructure.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the air curtain housing and inlet screen weekly; remove debris and wash with mild detergent to maintain airflow. Lubricate motor bearings per manufacturer schedule and tighten mounting hardware quarterly to prevent vibration. Replace worn seals and inspect electrical connections for corrosion; verify 120 volts supply and phase alignment before service. Balance airflow after adjustments and document maintenance dates for CSA compliance and operational continuity.