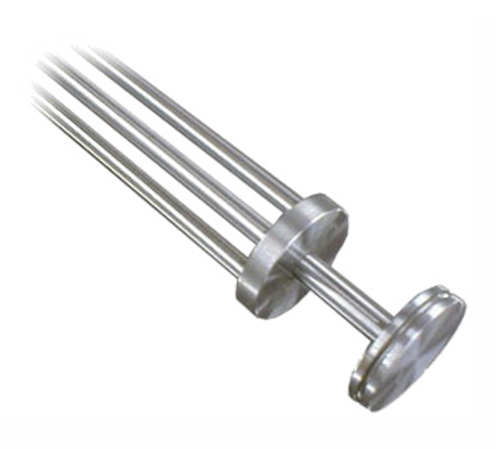

Engineers designed the star donut plunger to convert standard Type B and F depositors for precise dough dispensing. This design enables uniform shapes and consistent frying results, allowing operators to achieve repeatable output and efficient changeovers.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug equipment before cleaning. Remove plunger and soak in warm water with mild detergent for 10–15 minutes. Scrub crevices with a soft brush to dislodge batter and grease. Rinse thoroughly with potable water and air dry or towel dry completely. Sanitize with EPA-approved solution per label directions. Reassemble only when dry. Clean daily to remove bacteria, reduce fire risk from grease buildup, improve efficiency, avoid breakdowns, and pass CSA inspections.#@@#Additional Info#@#Belshaw 7SC-SSX1-1/2 1.5" star donut plunger fits Type B and F depositors, requiring matching cylinder sizes. Stainless steel resists corrosion, ensures accuracy, and allows quick replacement for consistent ring shape and throughput in fry lines.#@@#General Info#@#Description #@#

Engineers designed the star donut plunger to convert standard Type B and F depositors for precise dough dispensing. This design enables uniform shapes and consistent frying results, allowing operators to achieve repeatable output and efficient changeovers.

The plunger is made from stainless steel, ensuring durability and resistance to corrosion during contact with dough and fryer environments. It is essential for each plunger to pair with a matching cylinder for proper sealing and consistent portioning.

The plunger dispenses 1.5 inches of dough per stroke, creating uniform donuts that minimize waste and enhance portion cost accuracy. This consistency helps production staff maintain uniform cook times and oil usage.

Designed for compatibility, the plunger works seamlessly with Type B and Type F depositors, facilitating easy integration into existing systems. Maintenance teams can quickly swap components when cylinders and plungers share the same sizing standards.

The component fits into existing depositor assemblies, allowing for quick replacement and minimal downtime during busy shifts. Technicians can perform routine cleaning and inspections efficiently, supporting ongoing production.

Each unit weighs around 1 pound, providing stability during rapid operation. Kitchen managers find it easy to manage inventory since units are shipped individually and can be installed without the need for calibration.

The star pattern ensures controlled dough release, promoting even expansion and oil contact during frying. Operators can monitor the quality of the finished product with fewer rejects, achieving a consistent appearance across batches.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Clean the Belshaw 7SC-SSX1-1/2 1.5" star donut plunger after each shift to prevent batter buildup and preserve cutter accuracy. Rinse with warm water, apply food-safe detergent, and brush seams and grooves; flush thoroughly. Sanitize per protocol and air-dry on a clean rack to avoid corrosion. Inspect the stainless steel surface and cylinder for nicks; replace any worn plunger.