The production of fried dough products can be optimized for high-volume frying lines, ensuring consistent cook profiles and uniform product shape. This durable tool is designed for continuous use in institutional and commercial kitchens.

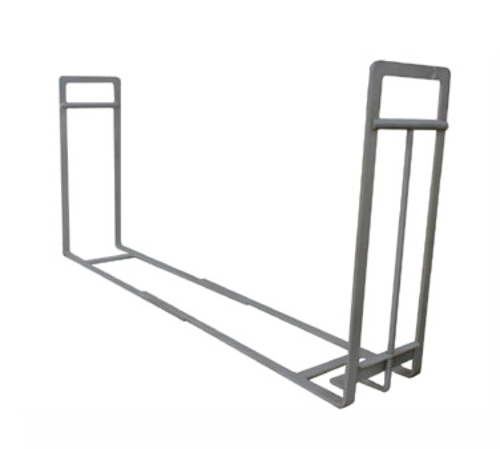

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug equipment and cool oil before work. Remove the Belshaw 718LG-1009 submerger and soak in warm water with a grease-cutting detergent for 10–15 minutes. Scrub with a non-abrasive brush, rinse with hot water, and air dry. Clean fryer vat and drains of residue; dispose of oil per local rules. Inspect seals and linkage; replace worn parts. Regular cleaning reduces bacteria, fire risk, energy use, breakdowns, and helps pass CSA inspections.#@@#Additional Info#@#Belshaw 718LG-1009 submerger fits 718 open kettle fryers and enables controlled immersion for consistent donut hole and loukoumades frying; made in USA, weighs 298 pounds, measures 64" H x 27" W x 40" D, and meets CSA electrical and safety standards.#@@#General Info#@#Description #@#

The production of fried dough products can be optimized for high-volume frying lines, ensuring consistent cook profiles and uniform product shape. This durable tool is designed for continuous use in institutional and commercial kitchens.

Engineered for precision, this mechanism guarantees consistent immersion times and uniform frying across each cycle, leading to predictable cook outcomes that minimize rework and waste.

Constructed with high-quality components and built in the USA, the assembly is resistant to corrosion and can endure repetitive thermal stress, resulting in fewer replacements and lower life-cycle costs compared to lighter-duty options.

This unit is compatible with 718 open kettle fryers, accommodating high throughputs typical in school cafeterias, hospital kitchens, and bakery lines, allowing managers to scale production without changing existing fryer setups or workflows.

Engineers have optimized the geometry to protect delicate items during transfer, preserving their shape and finish while helping production staff reduce scrap rates and improve portion consistency.

Access points have been designed for routine cleaning and component inspection, which helps minimize downtime during shift changes, allowing technicians to complete preventive tasks efficiently and maintain continuous operation schedules.

The system enhances cycle timing and decreases manual handling, resulting in lower labor intensity and improved safety in fast-paced environments. Supervisors note more predictable output and easier staff training when automated handling is implemented.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Belshaw 718LG-1009 submerger daily for wear and corrosion on welds, pins, and linkage. Replace damaged parts immediately to avoid failure. Lubricate pivot points with food-grade lubricant every 40 hours and wipe excess to prevent oil migration. Calibrate travel and immersion depth weekly for consistent cook times. Drain and filter oil per manufacturer schedule; inspect filter media and replace when contamination causes pressure drop.