Stop compromising flow for precision. This cylinder assembly delivers consistent portion control and robust construction to keep production moving in high-volume donut operations while meeting essential commercial safety standards for food service environments. Designed to integrate seamlessly with Type B and Type F depositor machines, this part restores accurate deposits and reduces waste during continuous frying cycles.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug equipment and disassemble the Belshaw 0035SSAX1-1/2 cylinder assembly. Rinse parts with warm water to remove batter residues. Clean stainless steel and aluminum surfaces with a mild detergent solution; scrub gently using non-abrasive pads. Sanitize food-contact areas per CSA and NSF guidelines. Dry components completely and inspect seals for wear; replace as needed. Reassemble and test operation before returning to service.#@@#Additional Info#@#Belshaw's 0035SSAX1-1/2 1.5" Type B and F depositor cylinder fits commercial donut systems, has a stainless steel kettle, meets ETL, CSA, NSF standards, weighs 1 pound, and allows for easy maintenance and part replacement.#@@#General Info#@#Description #@#

Stop compromising flow for precision. This cylinder assembly delivers consistent portion control and robust construction to keep production moving in high-volume donut operations while meeting essential commercial safety standards for food service environments. Designed to integrate seamlessly with Type B and Type F depositor machines, this part restores accurate deposits and reduces waste during continuous frying cycles.

#@@# High-Volume Accuracy#@#

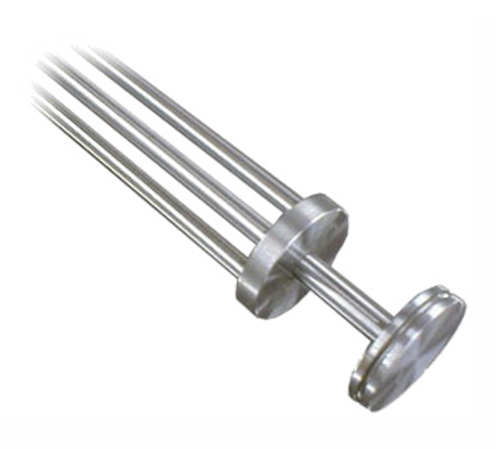

This component maintains a fixed 1.5-inch dispensing diameter to ensure repeatable portion weights and uniform cook times. Operators achieve predictable output that minimizes rework and enhances product consistency across thousands of units.

#@@# Durable Construction#@#

Manufacturers fabricate the cylinder from stainless steel combined with aluminum body elements to resist corrosion and maintain dimensional stability. Staff experience fewer replacements due to mechanical wear, which reduces parts spending over time.

#@@# Compliance Ready#@#

This assembly carries ETL and CSA recognition and meets NSF guidelines for food contact applications, supporting regulatory inspections and procurement requirements. Maintenance teams can document compliant equipment for audits without needing additional retrofits.

#@@# Easy Integration#@#

Technicians can install the cylinder assembly into compatible Type B and Type F depositors without extensive modifications, using existing mounting points and seals. Service teams perform swaps quickly during scheduled maintenance windows, restoring production with minimal downtime.

#@@# Cleanability and Hygiene#@#

Designers finish wet surfaces for straightforward cleaning and sanitizing, allowing line crews to maintain sanitary conditions between shifts. Supervisors observe faster turnover during sanitation cycles and lower microbial risk due to accessible surfaces.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Belshaw 0035SSAX1-1/2 cylinder assembly regularly for optimal performance. Clean stainless steel surfaces after each shift with food-safe detergent and warm water; rinse and dry to avoid residue and corrosion. Disassemble seals and gaskets weekly for inspection and replace any deformed or cracked components. Lubricate moving parts with NSF-registered lubricant monthly. Check fasteners and mounting hardware every 30 days, torquing to specifications.