Stop wasting time and risking glass damage at busy service points. This manual glass washer cleans and polishes with controlled friction, allowing staff to process high volumes of stemware quickly while preserving fragile rims. Designed for countertop use, it combines a compact footprint with three dedicated brushes to deliver consistent results through repeated cycles.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the unit before cleaning. Remove brushes and wash with warm, soapy water; rinse and air dry. Wipe the suction cup base and exterior with a non-abrasive cleaner. Inspect brushes for wear and replace when bristles splay. Clean surrounding counters and drain areas to remove grease and debris. Service coils and vents on nearby equipment regularly to reduce fire risk and lower utility use. Maintain records to meet CSA and health inspections.#@@#Additional Info#@#Bar Maid GWM-300 manual glass washer is 8" H x 9.5" W and uses three brushes with a suction cup base for secure mounting, enabling rapid glass cleaning in high-volume bar operations while meeting CSA standards.#@@#General Info#@#Description #@#

Stop wasting time and risking glass damage at busy service points. This manual glass washer cleans and polishes with controlled friction, allowing staff to process high volumes of stemware quickly while preserving fragile rims. Designed for countertop use, it combines a compact footprint with three dedicated brushes to deliver consistent results through repeated cycles.

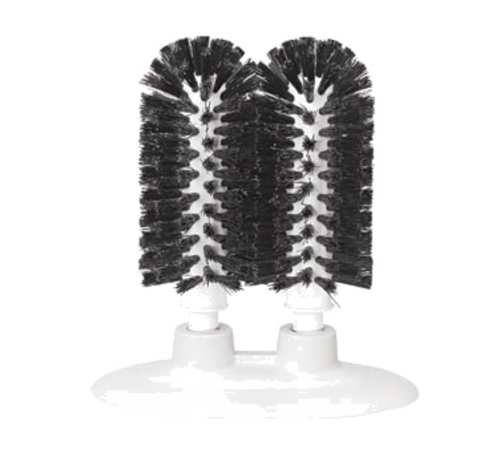

#@@# Brush Arrangement#@#

Three brushes are arranged in a triangular pattern to contact all glass surfaces simultaneously, minimizing the need for multiple passes. Operators achieve uniform cleaning action across bowls, stems, and bases while maintaining a steady workflow.

#@@# Compact Footprint#@#

The unit measures 8 inches high by 9.5 inches wide, fitting snugly into tight bar stations and prep counters without obstructing service. Managers can free up counter space for other tools while keeping cleaning steps within easy reach of the service line.

#@@# Suction Base#@#

A suction cup base secures the washer to flat surfaces, preventing movement during use and enhancing operator safety. Staff maintain workspace stability during high throughput periods, which reduces the risk of breakage.

#@@# Manual Operation#@#

The manual design eliminates reliance on power and simplifies training for short cleaning cycles between shifts. Teams can control pressure and motion to adjust cleaning intensity based on glass thickness and soil level.

#@@# Durable Brushes#@#

Brushes designed for wet cleaning provide effective scrubbing while minimizing abrasion to delicate rims. Supervisors can extend the usable life of stemware and reduce replacement frequency through consistent, gentle contact.

#@@# Case Quantity#@#

Packaging groups six units per case to facilitate inventory planning for multi-site operations or large bar programs. Procurement staff can allocate stock across locations more efficiently and simplify reorder cycles based on usage patterns.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Clean brushes after each shift by flushing warm water through bristles and rotating them to remove residue. Inspect suction cup base daily and replace if cracks appear to maintain secure mounting. Sanitize components with a 200 ppm chlorine solution for 60 seconds, then rinse with potable water. Lubricate moving parts monthly with food-grade lubricant. Calibrate washer alignment weekly to ensure consistent wash coverage and reduce glass breakage risks.