Stop underdelivering during peak service. This submersible glass washer combines continuous run capability with robust stainless steel construction to sustain high throughput and consistent cleaning results in busy bars, restaurants, hospitals, and campuses. Operators gain a compact, electric rotary system that fits counter spaces while delivering commercial performance through engineered components and safety features.

LongDescription#@#Glass Pro Glass Washer, submersible, electric, 1/3 HP with automatic overload safety, 5 brushes ( (4) 6" & (1) 6 3/4"), continuous run, bronze bearings, stainless steel construction, 115v/60/1-ph, includes: GFI plug, UL, CSA#@@#Cleaning Instructions#@#Unplug unit before cleaning. Remove brushes and soak in warm soapy water; scrub with a soft brush and rinse. Wipe stainless steel exterior with non-abrasive cleaner and a soft cloth. Flush drain and inspect seals for wear; replace damaged seals. Clean ventilation and condenser areas to prevent grease buildup and fires. Dry all components thoroughly before reconnecting power to maintain safety and equipment life.#@@#Additional Info#@#Bar Maid’s Glass Pro AA-SUB stainless steel washer runs on 115v/60/1‑Ph power with a 1/3 HP motor, five brushes, and overload protection.#@@#General Info#@#Description #@#

Stop underdelivering during peak service. This submersible glass washer combines continuous run capability with robust stainless steel construction to sustain high throughput and consistent cleaning results in busy bars, restaurants, hospitals, and campuses. Operators gain a compact, electric rotary system that fits counter spaces while delivering commercial performance through engineered components and safety features.

#@@# Stainless Steel Construction#@#

Engineers built the unit with a full stainless steel shell and components to resist corrosion and simplify sanitation routines in high-use settings. Technicians will appreciate durable surfaces that withstand frequent chemical exposure and the mechanical stresses of continuous operation.

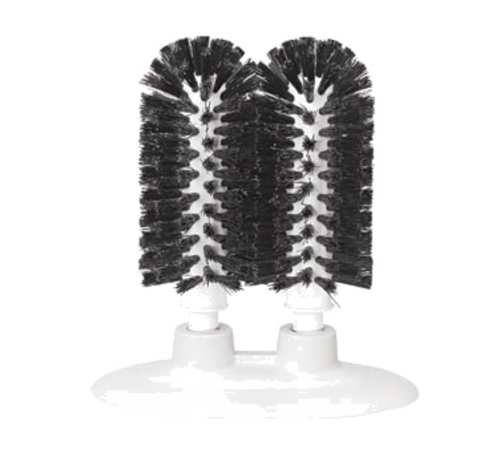

#@@# Rotary Brush System#@#

The machine uses a rotary brush arrangement with five brushes, including four 6-inch and one 6 3/4-inch brush, to scrub glassware efficiently on all sides. Staff will notice reduced rework because the brushes contact internal and external surfaces, cutting cycle times for continuous service lines.

#@@# Submersible Motor Drive#@#

A 1/3 HP submersible motor provides direct drive power while maintaining compact dimensions, enabling reliable torque for cleaning without occupying large footprints. Maintenance teams benefit from bronze bearings that lower wear rates and extend service intervals.

#@@# Electrical Safety Features#@#

The unit operates on 115v, 60 Hz, single-phase power and ships with a GFI plug for ground fault protection to meet standard electrical safety expectations in commercial environments. Facility managers gain peace of mind from the included UL and CSA listings that document compliance with recognized testing bodies.

#@@# Continuous Run Capability#@#

Designed for continuous operation, the washer supports back-to-back cycles during high demand periods without frequent cool-down requirements.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect brushes weekly and replace worn units to maintain consistent scrub action and reduce glass breakage. Flush the reservoir daily and remove sediment to prevent bacterial growth. Verify GFI plug and 115v wiring monthly; tighten connections and test operation under load. Lubricate bronze bearings per manufacturer interval and check for shaft play. Clean stainless surfaces with mild detergent and rinse thoroughly to prevent corrosion.