Stop sacrificing speed for cleanliness when your operation demands consistent, repeatable glass washing performance. This upright electric glass washer offers continuous operation and robust stainless steel construction to support fast-paced bars and backbars. Professionals gain a compact, reliable unit that integrates grounded electrical safety and serviceable components for minimal downtime.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the unit and lock out power before cleaning. Remove brushes and soak in warm water with mild detergent for 10–15 minutes, then scrub with a soft brush and rinse. Wipe stainless steel surfaces with non-abrasive cleaner and a soft cloth. Clean motor canopy and splashguard carefully to avoid moisture on sealed bearings. Inspect seals and replace if worn. Clean condenser coils or vents to maintain efficiency and reduce fire risk. Dry all parts completely before restoring power.#@@#Additional Info#@#Bar Maid A-200 glass washer runs on 115v/60Hz/1-Ph with a 1/3 HP motor, five brushes (four 6" and one 7-1/2"), stainless steel, sealed motor, splashguard, ETLus listed, GFI plug, Made in USA, weighs 27 pounds.#@@#General Info#@#Description #@#

Stop sacrificing speed for cleanliness when your operation demands consistent, repeatable glass washing performance. This upright electric glass washer offers continuous operation and robust stainless steel construction to support fast-paced bars and backbars. Professionals gain a compact, reliable unit that integrates grounded electrical safety and serviceable components for minimal downtime.

#@@# Motor Durability#@#

The unit features a 1/3 HP motor designed for continuous operation, delivering steady brush rotation under heavy cycles. Technicians will appreciate the enclosed motor with sealed lower bearings that minimize contamination and extend service intervals.

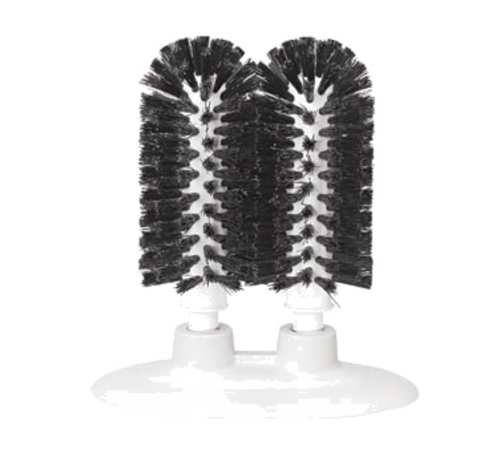

#@@# Brush Configuration#@#

Five brushes provide dedicated contact coverage, including four 6-inch brushes and one 7.5-inch brush for various glass sizes. Operators will experience consistent wash coverage for stemware and pint glasses, reducing rework and enhancing throughput.

#@@# Construction Materials#@#

Stainless steel construction resists corrosion in wet service environments and simplifies sanitation procedures. Maintenance crews will find surfaces easier to clean and less prone to pitting than painted steel assemblies.

#@@# Electrical Safety#@#

The unit includes a GFI plug and operates on 115v/60/1-ph power, ensuring compatibility with standard commercial circuits. Facility managers will note the grounded connection and compliant electrical specifications that support safe installation in service lines.

#@@# User Serviceability#@#

Design features include an accessible splashguard canopy and serviceable components that technicians can reach without complete disassembly. Engineers will reduce mean time to repair by quickly accessing bearings and brushes during scheduled maintenance.

#@@# Footprint Efficiency#@#

Compact dimensions of approximately 8 inches wide by 12 inches deep and 18 inches high save counter space in crowded bar stations.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect brushes daily and replace any with visible wear to maintain cleaning efficacy. Remove debris and soak brushes weekly in a sanitizing solution per local code. Flush internal water lines monthly and verify GFI plug and electrical connections for 115v, 60 Hz, 1-Ph integrity. Lubricate accessible motor bearings per manufacturer schedule and check splashguard canopy for cracks. Clean stainless steel exterior with mild detergent and dry to prevent spotting.