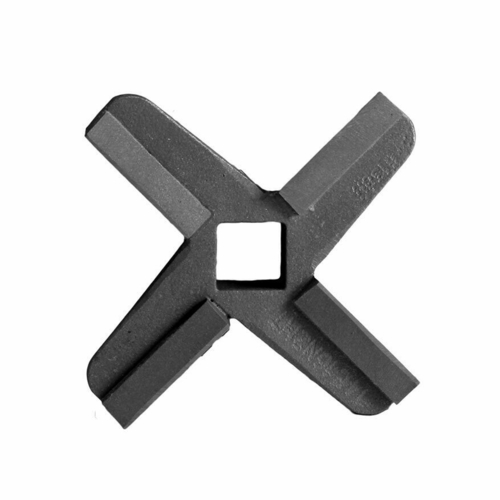

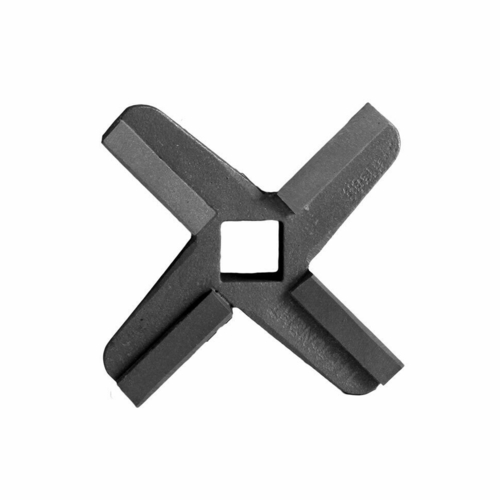

Stop compromising on precision when preparing high-throughput ground meat and sausage production. This forged steel chopper knife delivers consistent cutting geometry and durable edges that maintain grind quality across extended runs, reducing downtime for sharpening and replacement. Designed for direct fitment to a #32 hub, the one-piece construction simplifies installation and inventory management for busy operations.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug and disassemble the grinder. Remove the Alfa International 032 KN knife and wipe visible debris with a soft brush. Soak parts in warm water with mild detergent for 10–15 minutes. Scrub gently with a non-abrasive pad, rinse thoroughly, and dry completely to prevent corrosion. Sanitize food-contact surfaces per CSA guidelines. Reassemble only when all components are dry. Clean daily to reduce bacteria, limit fire risk, lower energy use, and extend equipment life.#@@#Additional Info#@#Alfa International 032 KN #32 hub chopper knife features a forged steel, one-piece L and W standard edge for meat choppers. It replaces Hobart P 15796, weighs 0.30 pounds, installs on #32 hubs, and meets CSA standards.#@@#General Info#@#Description #@#

Stop compromising on precision when preparing high-throughput ground meat and sausage production. This forged steel chopper knife delivers consistent cutting geometry and durable edges that maintain grind quality across extended runs, reducing downtime for sharpening and replacement. Designed for direct fitment to a #32 hub, the one-piece construction simplifies installation and inventory management for busy operations.

#@@# Hub Size#@#

Fits a standard #32 hub to ensure compatibility with common commercial grinders and choppers used in restaurants, institutions, and meat processing lines. Technicians achieve secure mounting and repeatable alignment, which preserves knife-to-plate concentricity and optimizes grind uniformity.

#@@# Material Construction#@#

Forged steel construction provides high tensile strength and impact resistance under continuous load, supporting sustained production without deformation. Operators observe stable edge retention that prolongs service intervals and reduces part turnover.

#@@# Edge Type#@#

Standard edge geometry balances initial sharpness with predictable wear characteristics for coarse and fine grinds. Production managers maintain product texture targets while minimizing the frequency of regrinding and setup interruptions.

#@@# Design Integration#@#

One-piece, solid profile eliminates assembly interfaces that introduce play or misalignment during operation. Maintenance teams perform quick swaps and maintain consistent knife-to-plate spacing, improving throughput and reducing scrap.

#@@# Replacement Fit#@#

Engineered as a disposable replacement for legacy part numbers, this knife simplifies parts sourcing and changeovers across multi-brand fleets. Purchasing departments standardize on a compatible unit to lower part complexity and expedite servicing.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Alfa International 032 KN #32 hub chopper knife before each shift and tighten the hub connection to CSA torque specs. Clean the forged steel blade after use with a food-safe degreaser and warm water; dry immediately to prevent corrosion. Sharpen the standard edge on a bench grinder using recommended angles, then balance and test on scrap product. Store in a dry rack to avoid damage and replace after signs of cracking or deformation.