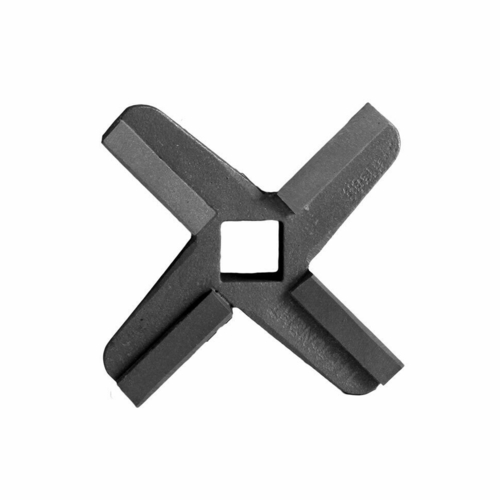

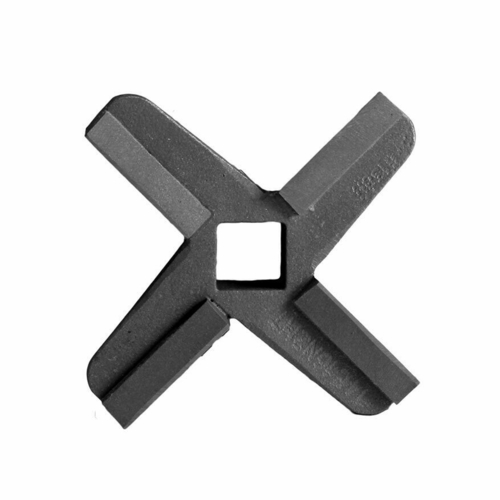

Engineered for high-throughput meat processing, this hardened tool steel chopper knife delivers consistent cutting performance and a long service life. Designed for compatibility with #12 hubs, the L and W configuration optimizes particle size control while allowing straightforward resharpening to maintain cutting quality over repeated use. Production teams benefit from repeatable results and reduced downtime through robust construction and reliable attachment methods.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug equipment and remove parts. Disassemble knife assembly and wipe visible debris with a soft brush. Prepare a mild detergent solution (use gallons or liters as needed) and scrub blades with a non-abrasive pad. Rinse with clean water and inspect hub #12 for wear. Dry components thoroughly to prevent corrosion. Reassemble and run a short test. Clean weekly or after heavy use to prevent contamination, reduce fire risk, lower energy use, extend equipment life, and ensure CSA compliance.#@@#Additional Info#@#Alfa International 012 KNH #12 hub hard-edge L and W chopper knife fits Alfa meat grinders. It has hardened tool steel, broached center holes, and cadmium-free induction-brazed cutting bars, allowing resharpening for extended life.#@@#General Info#@#Description #@#

Engineered for high-throughput meat processing, this hardened tool steel chopper knife delivers consistent cutting performance and a long service life. Designed for compatibility with #12 hubs, the L and W configuration optimizes particle size control while allowing straightforward resharpening to maintain cutting quality over repeated use. Production teams benefit from repeatable results and reduced downtime through robust construction and reliable attachment methods.

#@@# Hard Edge#@#

Hardened tool steel provides high wear resistance and stable edge retention under continuous operation. Operators notice extended intervals between sharpening cycles, which reduces maintenance labor and supports steady output.

#@@# Hub Compatibility#@#

Manufactured to fit #12 hub systems, the knife installs with precise alignment for secure coupling to the chopper assembly. Technicians achieve consistent rotor engagement and minimize vibration that can accelerate component wear.

#@@# Attachment Method#@#

Cutting bars attach using cadmium-free induction brazing, delivering a durable bond that resists loosening during heavy loads. Maintenance teams can expect fewer service interruptions due to fastener failure or bar separation.

#@@# Resharpenable Design#@#

Engineers designed the profile to accept resharpening without compromising hub fit or cutting geometry. Facilities preserve lifecycle value by restoring edge condition instead of replacing the entire knife assembly.

#@@# Precision Machining#@#

Broached center holes ensure accurate concentricity and stable mounting on the chopper hub, which maintains balanced rotation at production speeds. Supervisors observe lower vibration levels and improved cut uniformity across batches.

#@@# Origin and Compliance#@#

Produced in Mexico under strict manufacturing controls, the component aligns with industry part standards for meat chopper systems and displays consistent dimensional tolerances.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Alfa International 012 KNH #12 hub chopper knife before each shift and replace worn components promptly. Clean the hardened tool steel blade and broached center holes with a food‑safe degreaser and rinse; dry thoroughly to prevent corrosion. Remove cutting bars and verify cadmium-free induction brazes for cracks; resharpen blades on a certified grinder following manufacturer angles. Lubricate hub bearings lightly and torque fasteners to spec. Perform CSA checks per schedule.